In the final installment of Discoveries in Medicine’s three-part interview with William H. Fissell, M.D., co-developer of the iBAK, the first implantable bioartificial kidney, Fissell maps the path to clinical trials. Over two previous interviews, Fissell shared the vision for an implantable device that replaces failed kidneys and the bioengineering innovations that established feasibility.

Steps to Scaling

Discoveries: Your team has gone from concept to making a technologically and biologically feasible device. What lies ahead before this can be offered to patients with end-stage renal disease?

Fissell: Our plan now is to initiate clinical trials of our technologies within the lifetime of a person who has developed kidney failure today. We are envisioning a staged development pathway that will start with the HemoCartridge, our hemofilter, which could independently go to trial within two years, followed by the entire iBAK. By 2029, the iBAK could very conceivably be on the market.

This scaling pathway has three thrusts. First, we need to scale up the device to where it delivers 20 to 30 milliliters per minute of equivalent glomerular filtration – we are tiny right now.

Second, we plan to migrate all manufacturing processes out of our academic labs to Good Manufacturing Practice (GMP) facilities run by established FDA-approved vendors. Silicon membranes, polycarbonate housings, and the cells themselves must be produced in FDA-suitable plants instead of research laboratories.

“By 2029, the iBAK could very conceivably be on the market.”

Finally, we need to complete all sterility assurance and biocompatibility testing in Good Laboratory Practice (GLP) environments for FDA approval of the HemoCartridge as an investigational device, and the iBAK as an investigational combination product.

With a focused application of resources, these three steps are achievable in 18-24 months

Funding Needed to Cross the Finish Line

Discoveries: Where has your funding come from to date and what resources do you hope will support you as you go to market?

Fissell: We are betwixt and between the germinal work supported by NIH grants and the scaled-up production capability that attracts venture capital from investors (who expect a five-year return on investment). Yet, more than ever, sources of funding are crucial to our success as we move this ensemble of new technologies – all of them successful – to the stage where they will attract that investment capital.

We have had wonderful philanthropic support from families who have been touched by kidney disease and want something better for tomorrow. Now, we are looking for more angel investors and others who see the vision for what this could do for hundreds of thousands of people each year in the United States alone. This is a device that can restore vigor and independence to people with chronic kidney disease.

Discoveries: Aside from the monumental issue of funding and scaling up for production, what major work lies ahead for you?

Fissell: There’s a lot of work to be done to operationalize the discoveries that we’ve made.

Coverage of iBAK Implants

Discoveries: Do you foresee the Centers for Medicare and Medicaid Services (CMS) covering the cost of these devices and their implantation, plus patient care?

Fissell: As an alternative to transplant or dialysis, it would be cost-effective to do so. There are steps that can be taken to a CMS coverage decision, and recent legislation may have streamlined that process for all of us.

An Alternative to the Status Quo

Discoveries: How would you respond to resistance from payors or established players in the renal care market?

“This is a terminal solution for end-stage renal disease and a bridge to transplant that stands to save many, many lives.”

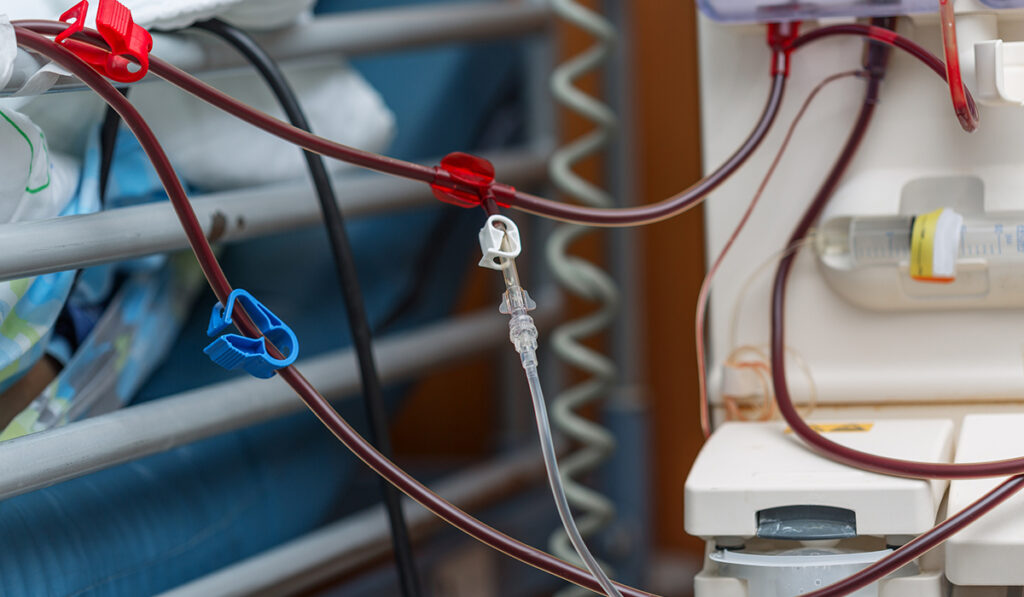

Fissell: Innovation in managing renal disease has lagged the entire rest of medicine for half a century. The new home dialysis equipment doesn’t begin to solve the problem. It’s still dialysis, which is traumatic to the body, not to mention that it is prone to leaks, operator error, and all kinds of problems. There are other technologies that aim to use vascular grafts and a port to enable continual dialysis with an external wearable, but these are in their infancy and the patient is still tied to a machine.

No other option for renal failure offers a life where the patient isn’t dependent on external devices, is free of rejection and immunosuppression risk, and relies on something systemically healthy and atraumatic. This is a terminal solution for end-stage renal disease and a bridge to transplant that stands to save many, many lives.

“We are committed to continuing our progress until every patient who desires an alternative to status quo dialysis can have an implantable device that sets them free.”

There will always be work to do, but the good news is huge. We are on the cusp of clinical trials. We have met every milestone of every NIH grant our team has been awarded. We are committed to continuing our progress until every patient who desires an alternative to status quo dialysis can have an implantable device that sets them free.

Part 1: Creating the First Implantable Bioartificial Kidney

Part 2: Challenges Overcome in Creation of Bioartificial Kidney